La purificación de la cera de abejas no se trata solo de derretir y filtrar, es una ciencia para preservar compuestos delicados mientras se eliminan los contaminantes. Ya sea un apicultor comercial o un distribuidor que suministra cera de primera calidad, dominar el procesamiento térmico controlado garantiza que su producto cumpla con los estándares de seguridad alimentaria sin comprometer sus beneficios naturales. Aquí le mostramos cómo lograr resultados de calidad profesional.

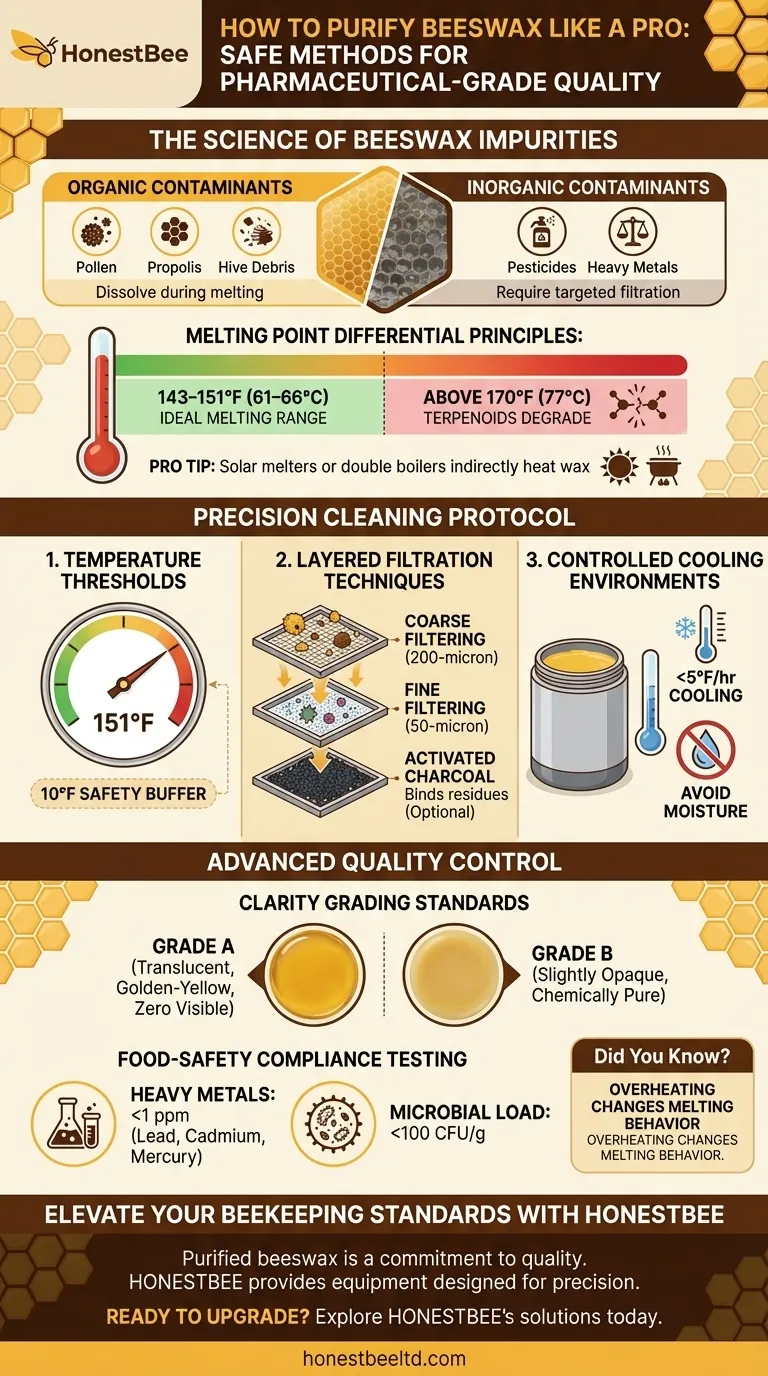

La ciencia de las impurezas de la cera de abejas

Contaminantes orgánicos vs. inorgánicos

La cera de abejas contiene naturalmente polen, propóleo y desechos de colmena (orgánicos), pero también puede albergar pesticidas o metales pesados (inorgánicos). ¿La diferencia clave? Las impurezas orgánicas a menudo se disuelven durante el derretimiento, mientras que las inorgánicas requieren una filtración específica.

Principios del diferencial de punto de fusión

La investigación muestra que la cera de abejas se derrite entre 143–151 °F (61–66 °C), pero sus terpenoides, compuestos responsables del aroma y las propiedades terapéuticas, se degradan por encima de los 170 °F (77 °C). Esta estrecha ventana exige precisión: el sobrecalentamiento decolora la cera y le quita sus beneficios.

Consejo profesional: Los fundidores solares o los baños maría calientan la cera indirectamente, lo que reduce los riesgos de quemaduras en comparación con los métodos directos en la estufa.

Protocolo de limpieza de precisión

Umbrales de temperatura para la preservación de la cera

- Rango de fusión ideal: 143–151 °F (61–66 °C)

- Límite absoluto: 170 °F (77 °C) para prevenir la degradación

- Margen de seguridad: Mantenga un margen de 10 °F por debajo del límite para la consistencia.

Técnicas de filtración en capas

- Filtración gruesa: Retire los desechos de la colmena con gasa o un tamiz de 200 micrones.

- Filtración fina: Utilice un filtro de 50 micrones para partículas microscópicas.

- Carbón activado (opcional): Se une a los residuos de pesticidas en aplicaciones de grado farmacéutico.

Entornos de enfriamiento controlados

Las caídas bruscas de temperatura provocan grietas. En su lugar:

- Enfríe la cera a <5 °F por hora en un recipiente aislado.

- Evite la exposición a la humedad para prevenir la turbidez.

Control de calidad avanzado

Estándares de calificación de claridad

- Grado A: Translúcido, amarillo dorado, sin partículas visibles.

- Grado B: Ligeramente opaco pero químicamente puro (aceptable para cosméticos).

Pruebas de cumplimiento de seguridad alimentaria

Los laboratorios externos pueden verificar:

- Metales pesados: Por debajo de 1 ppm para plomo, cadmio y mercurio.

- Carga microbiana: <100 UFC/g para uso tópico/cosmético.

¿Sabías que? El comportamiento de fusión de la cera de abejas cambia si se sobrecalienta, una señal de calidad comprometida detectable en pruebas de laboratorio.

Eleve sus estándares de apicultura con HONESTBEE

La cera de abejas purificada no es solo una mercancía; es un compromiso con la calidad que los apicultores y distribuidores pueden defender con orgullo. HONESTBEE proporciona a los apiarios comerciales y a los mayoristas equipos diseñados para la precisión, desde fundidores solares hasta filtros de grado de laboratorio, asegurando que su cera cumpla con los más altos estándares de la industria.

¿Listo para mejorar su proceso de purificación? Explore las soluciones de apicultura de HONESTBEE hoy mismo y ofrezca cera que se destaque en pureza y rendimiento.

Guía Visual

Productos relacionados

- Máquina eléctrica de láminas planas de cera de abejas con bandeja operativa para el procesamiento de cera

- Aplanadora y estampadora eléctrica con bandeja para apicultura

- Fundidor de miel cónico termostático profesional

- Miel de Concentración de Vacío de Calefacción Espesamiento de la máquina deshumidificador para la miel

- Máquina para cortar asas de colmena y apoyos de marco: Su máquina especializada en colmenas

Artículos relacionados

- Cómo los apicultores convierten la vieja cera de abejas en empresas rentables

- El Motor Oculto de la Colmena: Descifrando la Economía de la Producción de Cera

- Cómo separar la cera de abejas pura de los residuos de la miel: Métodos eficaces de reutilización

- Cómo optimizar la fusión de cera con vapor para obtener mayores rendimientos y operaciones más seguras

- Guía para separar la cera de abeja de la miel y sus usos